Eco Initiatives

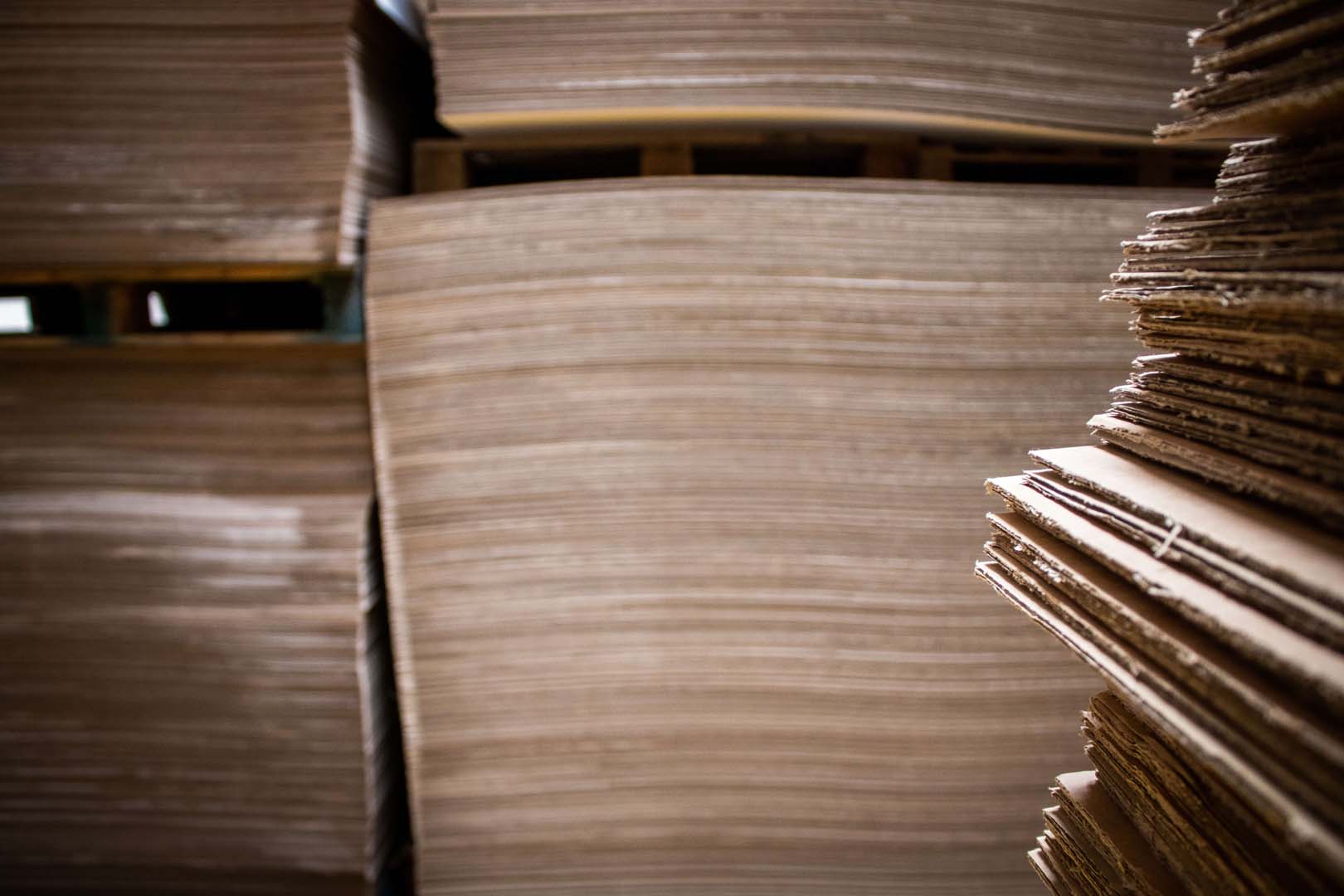

Corrugated cardboard & the environment.

Ever consider the environmental impact of packaging?

Most of us do. In a 2021 study by Statista, 82% of people in the UK and 80% of people worldwide stated their shopping habits were influenced by whether a product’s packaging was plastic free.

Fifty, twenty, or even ten years ago, customers would wander into a shop and browse without a moment’s thought on whether a product’s packaging was harmful to the environment.

Today, much like how we once drove cars without seatbelts and footballers smoked cigarettes at half-time, throwing away so much single-use plastic seems… somewhat short-sighted.

The world is more environmentally conscious today than ever before, and it’s affecting our shopping habits as well as our businesses.

Our Box Builder Reduces Waste

This is a feature on our website which allows you to type in the exact dimensions of any type of cardboard box you need.

First you choose the style of the box, then the length, width, depth, and strength, and finally the colour and quantity.

What does this mean for the environment?

It means far, far less cardboard going to waste per package, and less energy used to create further cardboard.

When you specify every aspect of the type of box you need, you can make sure that whatever product you’re packaging is secured neatly inside – no need for it to jangle around inside a box three times its size.

ASC Partner With One Tree Planted to Aid Reforestation

As a business, we like to hold ourselves accountable for the actions we take. Our long standing reputation in the cardboard box manufacturing industry means we have a duty to step up in matters that are of great importance to us. With that in mind, we are thrilled to say we have partnered with One Tree Planted in a bid to be a more sustainable, eco-friendly business and to lessen our environmental impact.

For every 1000 boxes manufactured by us, we will donate the necessary funds to plant one tree to aid in environmental conservation and restoration.

.

Our Corrugated Cardboard is Recyclable

We’re always working on refining the processes by which we create our cardboard to ensure it’s as efficient as possible.

We recycle any waste materials created during the box-making process, and anything that can’t be used again in our production process is recycled to make new paper.

In this way, we aim to protect the environment, while also keeping any potential wastefulness to an absolute minimum.

In addition, we encourage our customers to reuse and recycle our boxes, which helps to keep any environmental impact as low as possible.

Recycled corrugated cardboard keeps its strength

Thanks to the process by which we recycle our materials, there is no loss of durability when recycling.

Here are the stages of what happens to recycled cardboard:

Sorting and shredding

Different kinds of cardboard are recycled in different ways, so separating them before the process begins is crucial. Once sorted, the cardboard is shredded.

Pulping

The shredded cardboard is then mixed with water in large tanks, and is broken down into pulp.

Filtering

At this stage, the pulp likely contains elements that got mixed up with the cardboard, such as staples and sellotape. Several different tricks of the trade are used to remove these, including large magnets.

Drying and Pressing

The pulp will then be pressed, rolled and heated, until the water is completely evaporated and a shape begins to take form.

Resizing

When the pulp has dried, it is in the form of enormous rolls. These can then be cut and layered to turn it into cardboard – ready to start the process all over again!

Our Corrugated Cardboard is Completely Biodegradable

For a piece of corrugated cardboard to decay completely and be reclaimed by the environment, it takes around one year – at a maximum.

Different climates and weather can accelerate this process.

This means that when you use corrugated cardboard for your packaging, you can do so comfortable in the knowledge that whatever your customers do with their packaging, it won’t present any kind of problem to the environment at large.